Introduction

Kratom, a tropical tree native to Southeast Asia, has been used for centuries for its medicinal properties. Today, Kratom capsules are a popular way to consume this powerful herb, offering a convenient and precise dosage. But how are these capsules made? This article delves into the intricate process of transforming Kratom leaves into the capsules you find on store shelves, ensuring quality, potency, and safety.

Understanding Kratom

What is Kratom?

Kratom (Mitragyna speciosa) is a tree native to Southeast Asia, particularly Thailand, Malaysia, and Indonesia. Its leaves contain alkaloids, primarily mitragynine and 7-hydroxymitragynine, which interact with opioid receptors in the brain, producing stimulant and sedative effects depending on the dosage.

Historical Background

For centuries, Kratom has been used in traditional medicine in Southeast Asia to alleviate pain, boost energy, and treat various ailments. It has gained popularity in the Western world over the past few decades, leading to increased interest and consumption.

Types of Kratom Strains

Kratom is categorized into various strains based on the color of the leaf veins and the region where it is grown. The primary strains are red, green, and white vein, each offering unique effects and benefits.

The Importance of Quality Control

Sourcing Kratom Leaves

The quality of Kratom capsules begins with sourcing high-quality leaves. Reliable suppliers from Southeast Asia ensure the leaves are grown without pesticides and harvested sustainably.

Ensuring Purity and Potency

To maintain the integrity of the Kratom, suppliers must ensure that the leaves are free from contaminants such as heavy metals, bacteria, and molds. This involves rigorous testing and adherence to strict quality standards.

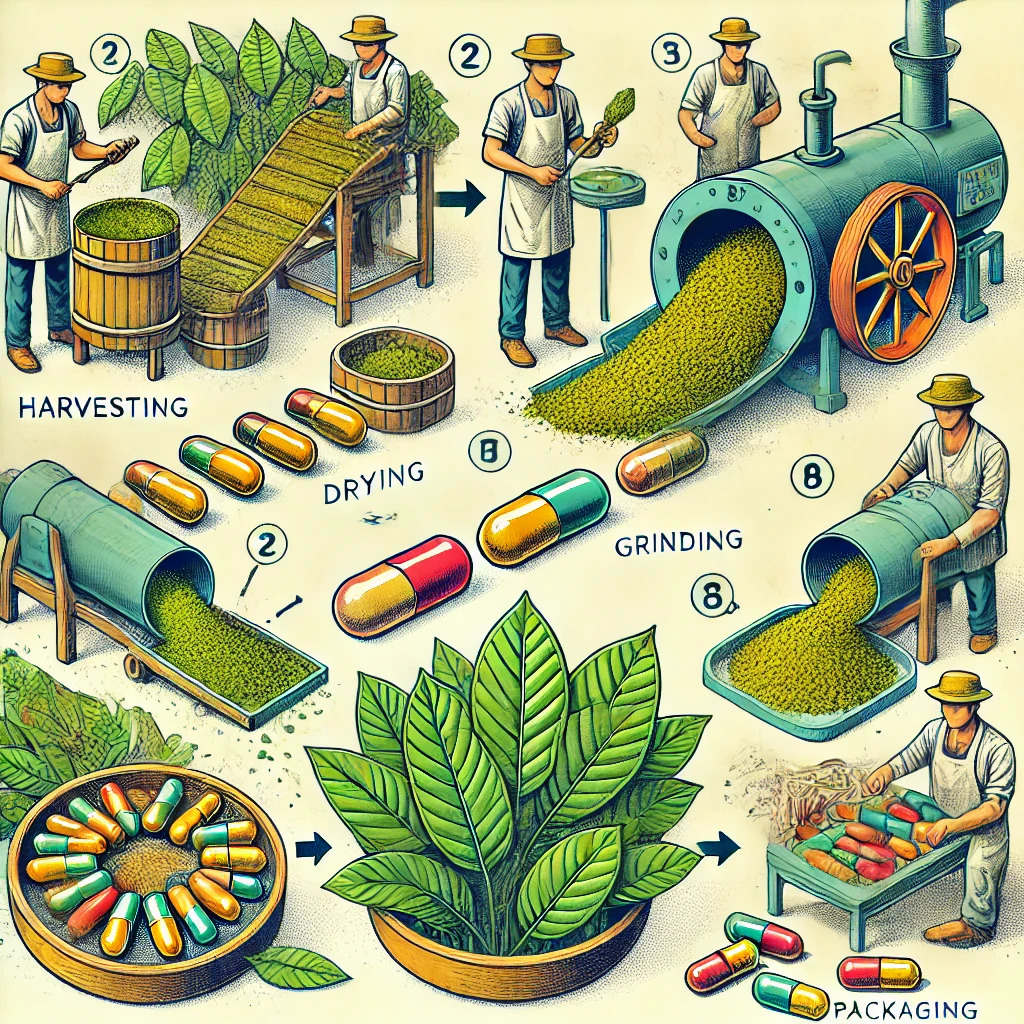

Harvesting Kratom Leaves

Optimal Harvesting Time

Kratom leaves are harvested at different times to produce varying alkaloid profiles. The maturity of the leaves affects their potency, with older leaves generally containing higher levels of active compounds.

Sustainable Harvesting Practices

Sustainable practices are crucial for the long-term availability of Kratom. This includes selective picking and ensuring the health of the trees and surrounding ecosystem.

Processing Kratom Leaves

Cleaning and Drying

Once harvested, the leaves are thoroughly cleaned to remove dirt and other impurities. They are then dried under controlled conditions to preserve their alkaloid content.

Grinding into Powder

The dried leaves are ground into a fine powder. This step is critical as the consistency of the powder affects the dosage and encapsulation process.

Encapsulation Process

Measuring the Dosage

Accurate dosing is vital for the effectiveness and safety of Kratom capsules. The powder is carefully measured to ensure each capsule contains a precise amount of Kratom.

Choosing Capsule Material

Capsules are made from either gelatin or vegetable cellulose, catering to different dietary preferences. The material must be compatible with Kratom and maintain its potency.

Filling the Capsules

Automated machines are typically used to fill capsules, ensuring uniformity and efficiency. The capsules are then sealed to prevent any contamination.

Packaging and Storage

Ensuring Freshness

To maintain the effectiveness of Kratom, capsules are stored in airtight containers, away from light, heat, and moisture. This helps preserve the alkaloids and extend the shelf life.

Labeling and Compliance

Packaging includes detailed labeling with information about the strain, dosage, and usage instructions. Compliance with regulatory standards is essential to ensure consumer safety and trust.

Quality Assurance and Testing

Laboratory Testing

Every batch of Kratom capsules undergoes rigorous laboratory testing to ensure it meets quality and safety standards. Tests include checking for alkaloid content, contaminants, and overall purity.

Ensuring Consistency

Consistency in potency and quality is crucial for consumer trust. Regular testing and quality control measures help maintain high standards across all batches.

Benefits of Kratom Capsules

Convenience and Portability

Kratom capsules offer a convenient way to consume Kratom without the need to measure out doses or deal with the bitter taste of the powder. They are easy to carry and use on the go.

Precise Dosage Control

Each capsule contains a precise amount of Kratom, ensuring consistent effects and reducing the risk of over or under-dosing.

Frequently Asked Questions About Kratom Capsules

Q. How long do Kratom capsules take to work?

A. Kratom capsules typically take 20-30 minutes to start working, as the capsules need to dissolve in the stomach first.

Q. Are Kratom capsules safe?

A. When sourced from reputable suppliers and used responsibly, Kratom capsules are generally safe. However, it’s important to follow recommended dosages and consult a healthcare provider if you have any concerns.

Q. Can I make Kratom capsules at home?

A. Yes, you can make Kratom capsules at home using Kratom powder and empty capsules. However, it’s important to measure the powder accurately to ensure proper dosage.

Q. What are the common side effects of Kratom capsules?

A. Common side effects can include nausea, dizziness, constipation, and dry mouth. These are generally mild and can be minimized by following recommended dosages.

Q. How should Kratom capsules be stored?

A. Store Kratom capsules in a cool, dry place away from direct sunlight and moisture to preserve their potency and shelf life.

Q. Are there different types of Kratom capsules?

A. Yes, Kratom capsules can vary based on the strain of Kratom used (e.g., red, green, white vein) and the type of capsule material (gelatin or vegetable cellulose).

Conclusion

The process of making Kratom capsules is meticulous, ensuring that each capsule delivers consistent quality and potency. From sourcing and harvesting the leaves to processing, encapsulation, and packaging, every step is designed to maintain the integrity of the Kratom. As a convenient and precise way to consume this traditional herb, Kratom capsules offer numerous benefits while adhering to strict quality standards.