Introduction

In the world of fluid systems, whether in automotive, aerospace, or industrial applications, maintaining smooth and efficient fluid flow is critical for performance and safety. One of the key processes that ensure optimal flow efficiency is pipe deburring tool—the removal of small, unwanted imperfections or “burrs” from the surface of metal components. Although it might seem like a minor step in manufacturing, deburring plays a significant role in enhancing fluid systems’ efficiency and longevity. In this article, we will explore what deburring is, why it is crucial for fluid systems, and how it ultimately improves flow efficiency.

What is Deburring?

Deburring refers to the process of removing small imperfections, such as sharp edges, burrs, or rough surfaces, that occur as a byproduct of manufacturing processes like cutting, drilling, or welding. These burrs can cause various issues in fluid systems by disrupting smooth flow, increasing friction, and potentially leading to component wear or failure.

Deburring can be done manually or using advanced automated techniques, such as:

- Mechanical deburring (e.g., using grinders, files, or abrasive brushes)

- Thermal deburring (using high heat to remove burrs)

- Chemical deburring (dissolving burrs with chemical agents)

- Electrochemical deburring (using an electrical current to dissolve burrs)

Each method is chosen based on the material type, component complexity, and desired precision.

Why is Deburring Important for Fluid Systems?

In fluid systems, smooth surfaces are essential for reducing resistance and ensuring consistent flow. Even small burrs or rough edges can disrupt the fluid flow, leading to inefficiencies. Here are the key reasons why deburring is critical for fluid systems:

1. Eliminates Flow Blockages

Burrs can create partial blockages within pipelines, valves, and other fluid system components. These blockages restrict fluid movement, causing pressure drops and reducing the overall flow efficiency. Deburring ensures that the internal surfaces remain smooth and clear of obstructions, promoting consistent fluid movement throughout the system.

2. Reduces Turbulence

Turbulence in fluid systems can lead to energy loss and increased wear on components. Burrs create rough areas where turbulence is more likely to occur, leading to inefficient flow patterns. By deburring, the smoothness of the internal surfaces is restored, reducing the likelihood of turbulence and ensuring that the fluid flows in a more streamlined manner.

3. Prevents Wear and Tear

Burrs can scratch or gouge other components in contact with them, especially in high-pressure systems. Over time, this can lead to premature wear and tear, leading to leaks, breakdowns, and costly repairs. Deburring eliminates these sharp edges, preventing damage to components and extending the lifespan of the fluid system.

4. Improves System Efficiency and Performance

By ensuring smoother surfaces and eliminating obstructions, deburring directly enhances the performance of fluid systems. The process reduces friction, allowing fluids to move more freely and with less resistance. This increased flow efficiency results in better overall system performance, lower energy consumption, and improved operational reliability.

Deburring Techniques Used in Fluid System Manufacturing

There are several deburring techniques commonly applied in the production and maintenance of fluid systems:

1. Manual Deburring

Manual deburring is one of the most traditional methods. It involves using tools like files, scrapers, or abrasive brushes to remove burrs from a surface. While this method is labor-intensive, it is ideal for small, complex, or sensitive components that require precision.

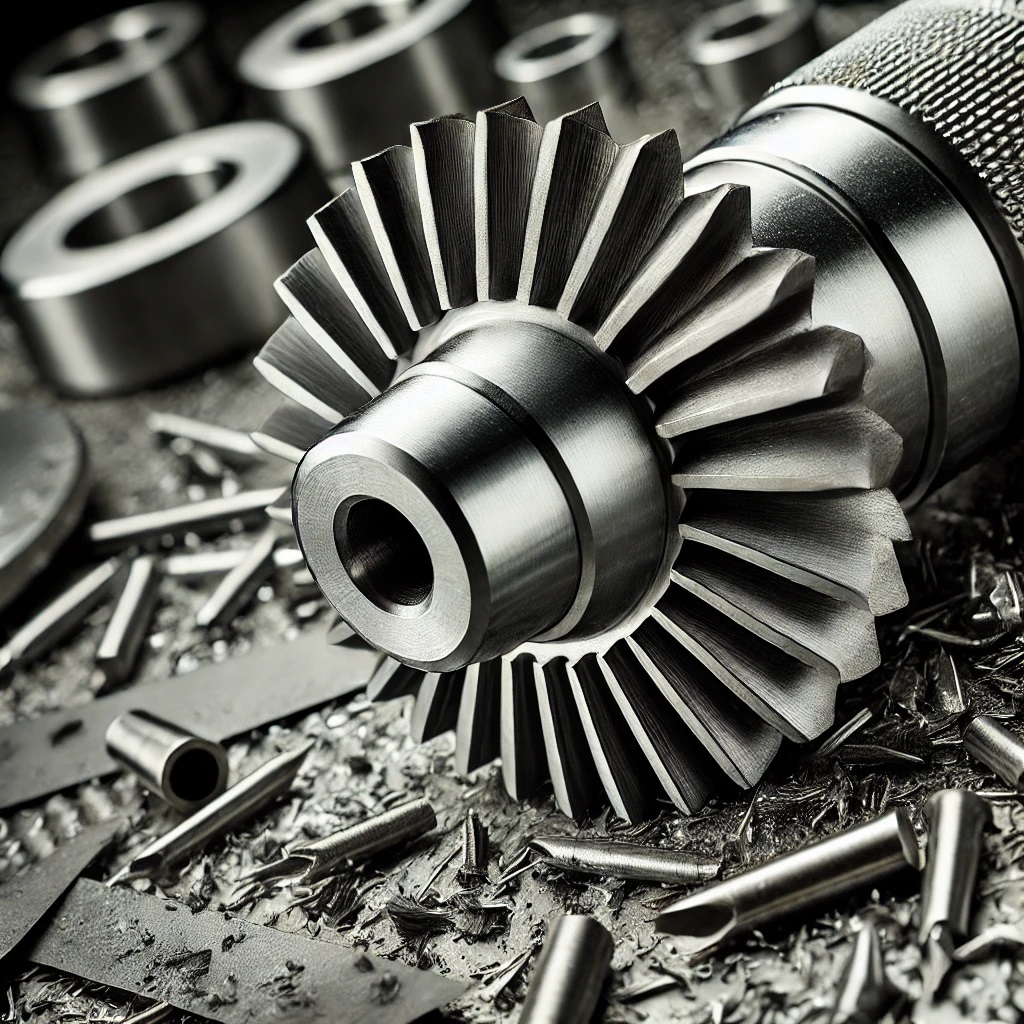

2. Mechanical Deburring

Mechanical deburring uses equipment such as tumblers, grinders, or sanders to remove burrs. This method is highly effective for large volumes of parts and components and is widely used in the manufacturing of pipes, valves, and fittings in fluid systems.

3. Thermal Deburring

Thermal deburring, also known as explosive deburring, involves exposing components to a high-temperature gas explosion inside a controlled chamber. The sudden heat burns away burrs without damaging the main material, making it ideal for removing small or hard-to-reach burrs in complex components.

4. Electrochemical Deburring

Electrochemical deburring uses an electrical current and a chemical solution to dissolve burrs from metallic surfaces. This method is especially effective for removing burrs from internal channels and other hard-to-reach areas, commonly found in fluid system components like valves and pumps.

Applications of Deburring in Fluid Systems

1. Automotive Fluid Systems

Deburring is commonly used in automotive manufacturing, especially for parts like fuel injectors, oil pumps, and cooling systems. These components must maintain precise fluid flow to ensure engine efficiency and prevent overheating or mechanical failures. Burrs in these systems can lead to blocked fuel injectors, reduced oil flow, and increased engine wear.

2. Aerospace Hydraulic Systems

In the aerospace industry, hydraulic systems control various aircraft functions, including landing gear, brakes, and flight control surfaces. Any disruption in hydraulic fluid flow could result in critical system failure. Therefore, deburring is crucial in ensuring smooth fluid flow and preventing component failure due to turbulence or wear.

3. Industrial Piping and Valves

Industries that rely on large-scale piping systems, such as oil and gas, chemical processing, and water treatment, must ensure their systems are free from blockages and leaks. Deburring helps to maintain smooth internal surfaces in pipelines and valves, reducing energy losses due to friction and ensuring efficient fluid transport.

Benefits of Deburring in Fluid Systems

1. Optimized Flow Rates

Deburring eliminates surface imperfections that can slow down fluid movement. By removing these imperfections, fluid can flow more freely, resulting in optimized flow rates and better system performance.

2. Increased Component Lifespan

By removing burrs that can cause wear and tear on critical components, deburring significantly extends the lifespan of valves, pumps, pipes, and other fluid system elements. This reduces the frequency of part replacements and the overall maintenance costs for industries relying on fluid systems.

3. Reduced Maintenance Costs

Deburring not only improves the initial efficiency of fluid systems but also contributes to long-term savings. Smoother components experience less wear, require fewer repairs, and are less likely to develop leaks or blockages over time. As a result, deburring reduces both preventive and reactive maintenance costs.

Conclusion

Deburring may seem like a minor step in the manufacturing of fluid systems, but its impact is substantial. From reducing flow blockages and preventing wear to enhancing system performance and extending component lifespan, deburring is critical in ensuring the efficiency and reliability of fluid systems across multiple industries. As technology continues to evolve, deburring methods will become even more advanced, further revolutionizing the production and maintenance of fluid systems.

FAQs About Deburring and Fluid Systems

1. What are the most common methods used for deburring?

The most common deburring methods include manual deburring, mechanical deburring, thermal deburring, and electrochemical deburring. Each method is chosen based on the material and component type.

2. How does deburring improve flow efficiency?

Deburring removes surface imperfections, such as burrs, that can obstruct fluid flow or create turbulence. Smoother surfaces allow fluid to flow more efficiently, reducing energy loss and improving system performance.

3. Is deburring necessary for all fluid systems?

While not all fluid systems require deburring, it is crucial for systems where smooth fluid flow is essential, such as automotive, aerospace, and industrial piping systems.

4. Does deburring increase component longevity?

Yes, deburring helps to remove sharp edges and rough surfaces that can cause wear and tear on fluid system components, significantly increasing their lifespan.

5. Can deburring be automated?

Yes, many deburring processes, such as mechanical and thermal deburring, can be automated, making them more efficient and consistent for large-scale production.