Introduction to Shot Peening

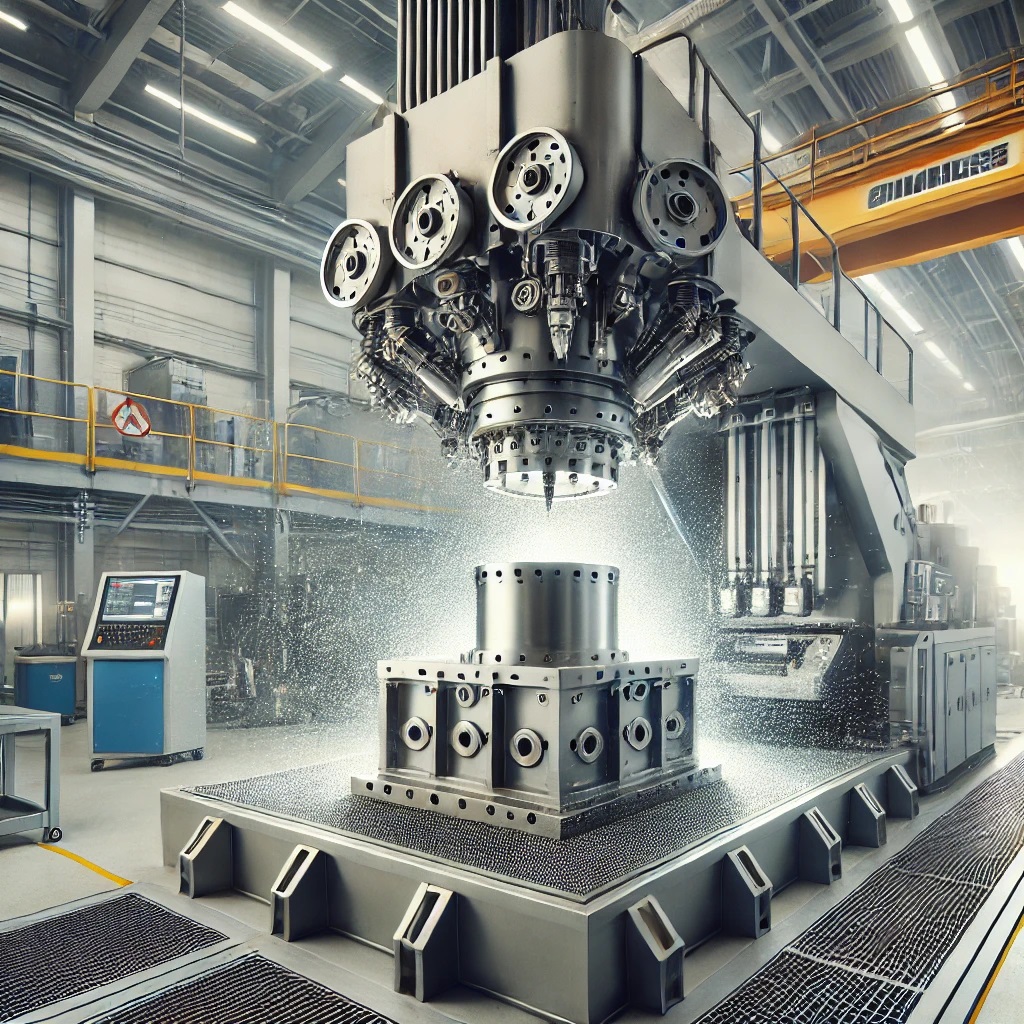

Shot peening is a surface treatment method where small spherical media, typically steel, glass, or ceramic, are propelled at high velocities to induce compressive stress on the surface of a material. This process strengthens the material and improves fatigue resistance, corrosion resistance, and crack prevention. Shot peening machines come in two main forms: portable and stationary. The choice between these depends on several factors, including application type, location, and project scope.

Key Differences Between Portable and Stationary Shot Peening Machines

1. Mobility and Flexibility

- Portable Machines: As the name suggests, portable shot peening machines offer the flexibility to be moved to different job sites. These machines are ideal for fieldwork, especially when parts cannot be transported to a facility for treatment. This mobility makes them highly suitable for industries such as construction, where equipment needs to be treated on-site.

- Stationary Machines: On the other hand, stationary shot peening machines are fixed in one location. They are typically installed in a facility and are better suited for high-volume, repetitive tasks. These machines excel in settings where components are small or can be easily transported to a central processing area.

2. Operation and Ease of Use

- Portable Machines: Portable shot peening systems are generally designed for ease of setup and operation. Many are lightweight and can be operated by a single person, making them ideal for jobs requiring quick adjustments. However, they may have limitations in terms of power and speed compared to their stationary counterparts.

- Stationary Machines: Stationary shot peening machines are often more complex and feature advanced automation for precision and consistency. These machines may require more skilled operators to handle intricate controls and settings. The benefit of this is higher accuracy and efficiency for large-scale production runs.

3. Cost Efficiency

- Portable Machines: For small-scale operations or fieldwork, portable machines are generally more cost-effective. They eliminate the need to transport components, which can reduce operational costs. However, they might have a higher per-unit cost for consumables due to their smaller capacity and reduced efficiency compared to stationary models.

- Stationary Machines: While stationary machines require a higher upfront investment, they offer better cost efficiency over time for high-volume operations. Their larger capacity and automated features lead to lower per-part treatment costs, making them ideal for industries with continuous production demands.

4. Application Scope and Flexibility

- Portable Machines: These machines are perfect for situations where the peening needs to happen on-site or where transporting components is impractical. Examples include large aircraft wings or heavy machinery parts. Portable machines also allow for more customization in handling unique job conditions, such as varying environmental factors.

- Stationary Machines: Stationary shot peening machines are optimized for batch processing and high-volume production. They’re ideal for small to medium-sized components, such as gears, springs, and other automotive parts. Due to their fixed nature, they are better suited for repetitive tasks where precision and consistency are critical.

5. Power and Performance

- Portable Machines: Although portable shot peening machines are generally less powerful than stationary models, advancements in technology have made modern portable units highly effective for field operations. However, they may not be able to handle the same level of precision and intensity required for certain industrial applications.

- Stationary Machines: Stationary shot peening machines are built for high-powered operations. They can process large batches of components quickly, making them ideal for industrial applications where performance and speed are paramount. They also offer more precise control over parameters such as shot velocity, coverage, and intensity.

Pros and Cons Summary

| Aspect | Portable Machines | Stationary Machines |

|---|---|---|

| Mobility | Highly mobile, can be used on-site | Fixed location, not mobile |

| Ease of Use | Quick setup, simple operation | Requires skilled operators for advanced settings |

| Cost | Lower upfront cost, higher consumable cost | Higher upfront cost, cost-effective for large-scale operations |

| Application Flexibility | Ideal for fieldwork and large components | Best for batch processing and repetitive tasks |

| Power | Moderate power, suitable for smaller jobs | High power, ideal for industrial-scale operations |

Conclusion

Choosing between a portable and stationary shot peening machine depends largely on your specific needs. Portable machines are perfect for on-site work, offering flexibility and ease of use, but they may fall short in terms of power and precision. Stationary machines, on the other hand, are ideal for high-volume, consistent production but come with higher upfront costs and less mobility.

Both types of machines serve distinct purposes in different industries. By considering factors such as mobility, ease of use, power, and cost efficiency, you can make the right choice to suit your project requirements.

FAQs

1. Can portable shot peening machines be used for large industrial tasks?

Portable shot peening machines can handle many industrial tasks but may not be as powerful or efficient as stationary machines. They are best suited for on-site applications or fieldwork where transporting components is impractical.

2. How do I know if I need a stationary shot peening machine?

If your operations involve high-volume production, repetitive tasks, and require precision, a stationary machine would be a better investment. These machines are designed for large-scale production and offer higher efficiency and lower per-part costs over time.

3. What are the maintenance requirements for portable vs. stationary machines?

Portable machines generally require less maintenance since they are used for smaller tasks and less frequently. However, stationary machines, due to their complexity and heavy-duty use, need regular maintenance to ensure optimal performance.

4. Are portable shot peening machines less effective than stationary ones?

Portable machines are not necessarily less effective but may not provide the same level of power, speed, or precision as stationary machines. They are designed for different types of work, particularly on-site jobs, where flexibility is key.

5. What industries benefit most from portable shot peening machines?

Industries like aerospace, construction, and heavy machinery repair benefit the most from portable shot peening machines, as these often require on-site surface treatment of large parts or equipment.