Shot peening is a crucial surface treatment process employed in various industries to enhance the fatigue life of metal components. This method involves bombarding the surface of a metal part with small spherical media, typically steel, ceramic, or glass beads, at high velocity. The process introduces compressive stresses on the surface of the material, preventing the propagation of cracks, which is the primary cause of metal fatigue.

Let’s dive into how shot peening machines function, their benefits, and the science behind why they are effective in preventing metal fatigue.

What is Metal Fatigue?

Metal fatigue occurs when a material is subjected to repeated cyclic stresses that are below the ultimate tensile strength of the material. Over time, small cracks form and propagate under cyclic loading, eventually leading to catastrophic failure. Fatigue failure can happen in everything from aircraft components to car engines, making it a critical consideration in design and maintenance.

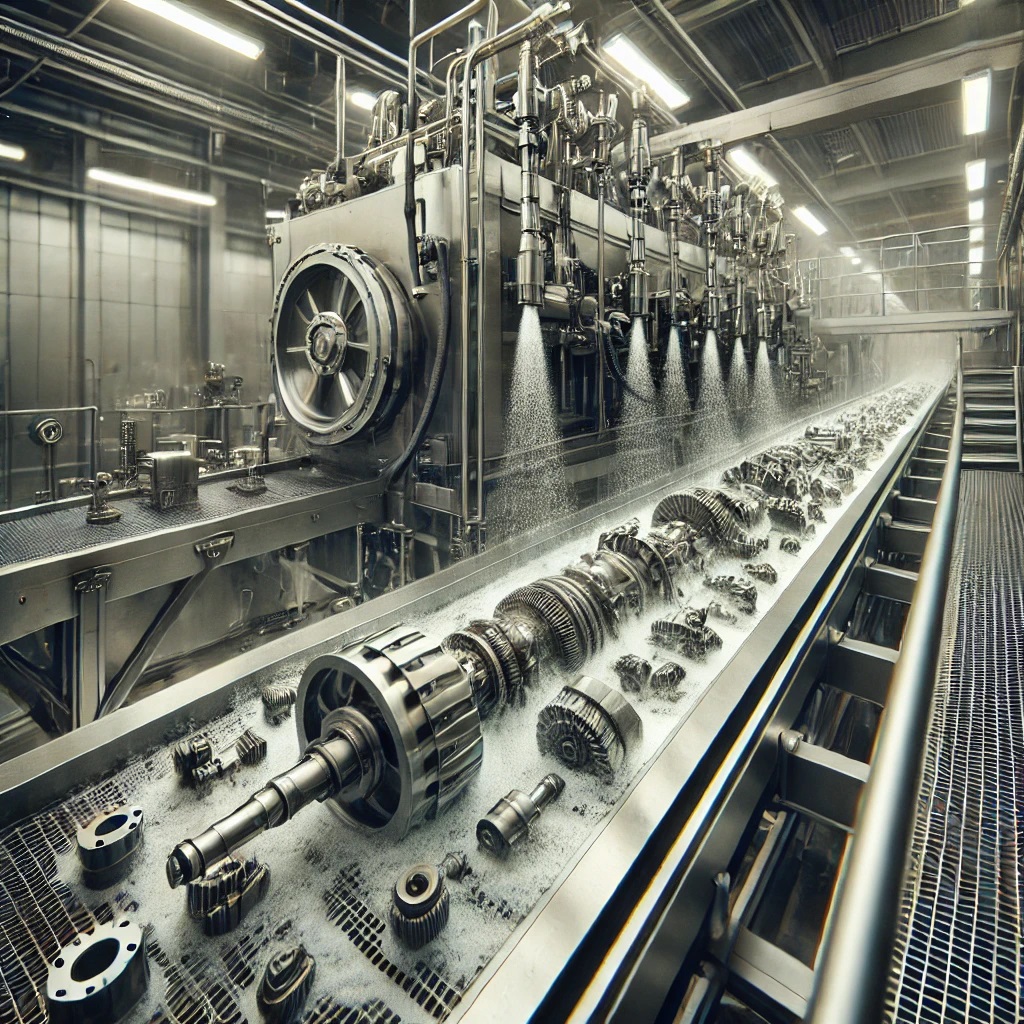

How Shot Peening Machines Work

Shot peening machines operate by projecting small, hard particles at high speed onto the surface of metal components. The impact of the shot creates small indentations or dimples on the surface, which causes the metal surface to yield. As the material tries to return to its original shape, compressive residual stress is introduced at the surface.

Key Components of Shot Peening Machines:

- Shot Media: Small spherical particles such as steel, glass, or ceramic.

- Projection Mechanism: Machines use compressed air, centrifugal force, or gravity to propel the shot.

- Control Systems: Advanced shot peening machines are equipped with precise control systems to monitor parameters such as shot velocity, angle, and coverage area to ensure consistency.

Process Flow:

- Preparation: The metal part is cleaned to remove any contaminants that might interfere with the process.

- Shot Bombardment: Small media particles are projected at the part’s surface, creating uniform indentations.

- Stress Induction: The high-energy impact introduces compressive stress, counteracting tensile stress that would cause fatigue cracks.

Why Shot Peening Prevents Metal Fatigue

The compressive stress induced by shot peening is essential in preventing metal fatigue because cracks cannot easily initiate or propagate in compressive regions. Metal fatigue cracks typically grow in areas subjected to tensile stress, where the material is being pulled apart. Shot peening counters this effect by embedding a compressive layer that shields the component from the detrimental effects of cyclic tensile stresses.

Science of Compressive Stress

- Residual Compressive Stress: The repeated dimpling from shot peening creates an even distribution of compressive stress. These stresses are crucial because they counteract the tensile forces that would otherwise lead to crack propagation.

- Surface Hardening: The surface of the material becomes harder and more resistant to wear. This hardness not only improves fatigue life but also increases the overall durability of the part.

Case Study: Aircraft Landing Gears

In critical applications like aircraft landing gears, shot peening has been widely adopted. Without it, the repeated stress from takeoffs and landings would quickly cause fatigue cracks, leading to costly and potentially dangerous failures. Through regular shot peening, the life of these components is greatly extended, ensuring safety and reliability.

Advantages of Shot Peening

1. Increased Fatigue Life

- The primary benefit of shot peening is the significant increase in fatigue strength. For many components, it can extend their fatigue life by as much as 1000%.

2. Resistance to Stress Corrosion Cracking

- Shot peening also helps in reducing stress corrosion cracking (SCC), a process where metals crack due to the combined influence of tensile stress and a corrosive environment.

3. Improved Surface Hardness

- The process enhances surface hardness, making the material more resistant to wear and tear, which is crucial for components subjected to harsh environments.

4. Enhanced Load-Carrying Capacity

- Shot peened parts can handle higher loads without the risk of premature failure, as the compressive layer helps absorb the stress, protecting the component from cracks.

5. Customizability

- The process can be tailored to specific applications by adjusting factors such as shot size, material, intensity, and coverage. This flexibility allows engineers to precisely control the depth and distribution of the compressive stresses.

Types of Shot Peening Machines

Several types of machines are available, depending on the application:

1. Air Blast Peening Machines

These machines use compressed air to propel the shot onto the surface. They offer great flexibility and are ideal for peening complex parts.

2. Wheel Blast Peening Machines

Here, a rotating wheel hurls the shot at high speeds. These machines are typically used in large-scale industrial applications where high productivity is required.

3. Robotic Shot Peening Machines

In applications requiring precise control over shot peening parameters, robotic systems are used. These machines are equipped with sensors and software to ensure uniform peening on complex geometries.

Factors Influencing Shot Peening Effectiveness

Several key factors determine the effectiveness of the shot peening process in preventing metal fatigue:

- Shot Size and Material: Different shot materials (steel, ceramic, glass) offer varying levels of hardness and density. The size and material must be selected based on the part’s material and the desired depth of compressive stress.

- Intensity: The energy with which the shot strikes the part’s surface must be carefully controlled. If the shot is too soft, it may not create enough stress. If it’s too hard, it may damage the part.

- Coverage: Full coverage is necessary to ensure uniform compressive stress. Incomplete coverage may leave areas vulnerable to fatigue cracking.

Maintenance and Quality Control

Maintaining shot peening machines is essential to ensure consistent performance. Regular checks on shot media, monitoring for wear, and recalibrating the projection system are necessary. Many modern shot peening machines feature automated monitoring systems to ensure that the shot velocity, coverage, and intensity remain within specified tolerances.

Conclusion

Shot peening is an indispensable process for enhancing the fatigue life of metal components, especially in industries where safety and reliability are paramount. By introducing compressive stresses at the surface of metal parts, shot peening effectively prevents crack initiation and propagation, which are the leading causes of metal fatigue. This technology has been proven in critical applications, including aerospace, automotive, and heavy machinery, offering a reliable means to increase durability, reduce maintenance costs, and improve overall component performance.

FAQs

1. What types of metals can be shot peened?

Shot peening can be applied to various metals, including steel, aluminum, titanium, and nickel alloys.

2. How often should parts be shot peened?

The frequency of shot peening depends on the application and the operating conditions. For highly stressed components like aircraft parts, regular intervals are recommended based on fatigue life studies.

3. Can shot peening damage a part?

If done incorrectly, shot peening can cause surface damage. However, when parameters like shot size, intensity, and coverage are properly controlled, the process is safe and effective.

4. Is shot peening a cost-effective process?

Yes, the increase in fatigue life and durability outweighs the costs of the process, especially in critical applications where part failure is not an option.

5. What is the difference between shot peening and sandblasting?

While both processes involve blasting a surface, sandblasting is primarily used for cleaning or surface preparation, whereas shot peening is used to improve mechanical properties by inducing compressive stress.