Introduction

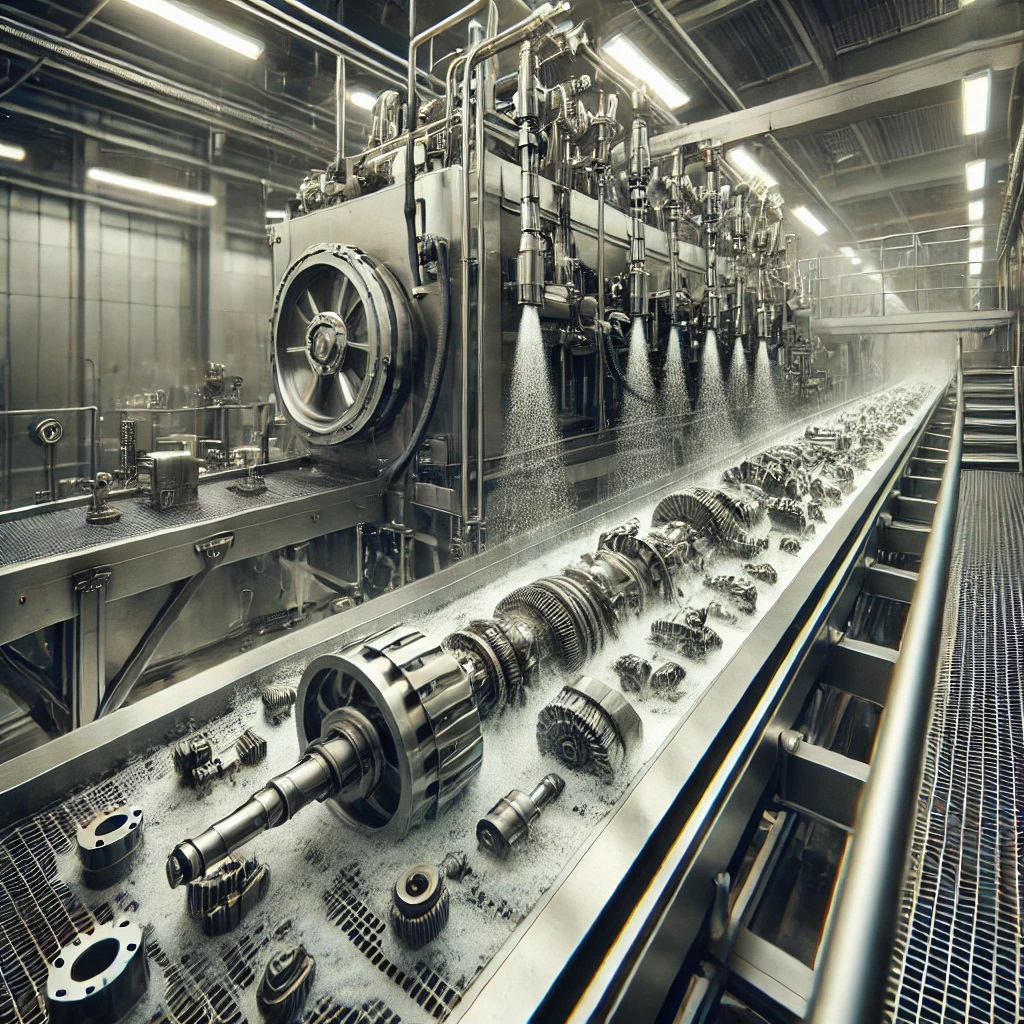

In various industries, keeping parts and components clean is essential for optimal performance. Poor cleaning can lead to defects, equipment failure, and even product recalls. Industrial parts washing systems are specifically designed to provide thorough cleaning, ensuring that every part is free of contaminants. Precision cleaning goes beyond ordinary washing, targeting microscopic particles and residues that could otherwise compromise the quality of the final product.

In this article, we will explore the key features of industrial parts washing systems and how to achieve precision cleaning with these systems.

Key Features of Industrial Parts Washing Systems for Precision Cleaning

1. Ultrasonic Cleaning Technology

One of the most effective ways to achieve precision cleaning is through ultrasonic cleaning technology. This system uses high-frequency sound waves to create microscopic bubbles that scrub every nook and cranny of the parts being cleaned. The bubbles reach areas that would otherwise be impossible to clean manually, making ultrasonic cleaning ideal for complex or intricate components.

Benefit: Removes even the tiniest contaminants from hard-to-reach areas, ensuring superior cleanliness.

2. Automated Cleaning Cycles

Industrial parts washing systems often come with programmable, automated cleaning cycles. These systems are designed to provide consistent, repeatable cleaning results by following pre-set programs. Automated cycles ensure that each part is cleaned to the same standard, which is essential for precision applications.

Benefit: Consistent cleaning quality and reduced human error.

3. Multi-Stage Cleaning Processes

Precision cleaning often requires multiple stages to completely remove contaminants. This could include pre-washing, rinsing, ultrasonic cleaning, and drying. Each stage serves a specific purpose, such as breaking down grease or flushing away loosened particles. Multi-stage cleaning systems ensure that even the most stubborn contaminants are fully removed.

Benefit: Comprehensive cleaning that tackles various types of contamination, leaving parts spotless.

4. Customizable Cleaning Parameters

Different materials and parts require different cleaning approaches. Modern industrial parts washing systems allow you to customize parameters like water temperature, pressure, and chemical concentration to suit the specific needs of the parts being cleaned. This flexibility is crucial for achieving precision cleaning across different components.

Benefit: Tailored cleaning solutions ensure compatibility with a wide range of materials and contamination levels.

5. Environmentally Friendly Cleaning Agents

Choosing the right cleaning agents is crucial for achieving precision cleaning without damaging the parts or the environment. Modern parts washing systems use environmentally friendly cleaning agents that effectively remove contaminants without the need for harsh chemicals. These agents can be water-based, biodegradable, and free from volatile organic compounds (VOCs).

Benefit: Safe for the environment while providing effective cleaning for sensitive components.

6. Drying Systems

After cleaning, parts must be dried thoroughly to prevent water spots or corrosion. Many precision cleaning systems integrate advanced drying solutions such as air blowers or vacuum drying. These systems remove moisture quickly and evenly, ensuring that parts are ready for immediate use or further processing.

Benefit: Ensures that cleaned parts remain spotless and corrosion-free.

Best Practices for Achieving Precision Cleaning

1. Regular Maintenance of Washing Systems

To achieve the best precision cleaning results, regular maintenance of industrial parts washing systems is essential. This includes cleaning the filters, inspecting the ultrasonic transducers, and ensuring that all mechanical parts are in good condition. Regular maintenance prevents contamination buildup and ensures that the system operates at optimal efficiency.

2. Proper Chemical Dosing

Using the correct amount of cleaning agent is crucial for precision cleaning. Overdosing can lead to residue buildup, while underdosing may result in incomplete cleaning. Automated dosing systems, which many modern washing machines feature, ensure that the right amount of chemical is used for each cleaning cycle.

3. Correct Part Placement

For ultrasonic cleaning, proper part placement in the washing basket is critical. Parts should be evenly spaced to allow the ultrasonic waves to penetrate all areas. Overcrowding parts can block the cleaning action, leading to inconsistent results.

4. Monitoring and Testing Cleanliness

Regular monitoring and testing of cleanliness levels are necessary to maintain precision cleaning standards. This can be done using various methods, including visual inspections, particle count tests, and surface analysis. Monitoring ensures that the washing system continues to meet cleanliness requirements.

Conclusion

Precision cleaning is a vital part of ensuring high-quality performance in industries where even the slightest contamination can cause issues. By utilizing industrial parts washing systems equipped with features such as ultrasonic cleaning, automated cycles, and multi-stage processes, you can achieve superior cleaning results. Regular maintenance, proper chemical dosing, and ongoing cleanliness monitoring are essential practices to ensure your washing system delivers the precision required for critical applications.

By investing in the right technology and following best practices, you can optimize your cleaning processes, reduce downtime, and improve the longevity and reliability of your industrial parts.

FAQs

1. What is the role of ultrasonic cleaning in precision cleaning?

Ultrasonic cleaning uses high-frequency sound waves to create bubbles that scrub away contaminants from intricate parts. It is highly effective at removing particles from hard-to-reach areas, making it ideal for precision cleaning.

2. Can I use any cleaning agent in an industrial parts washing system?

No, you should choose a cleaning agent that is compatible with the materials you’re cleaning and the washing system. Environmentally friendly, biodegradable agents are recommended to avoid damage to parts and to minimize environmental impact.

3. Why is drying important in the precision cleaning process?

Thorough drying prevents water spots and corrosion, especially for parts that are sensitive to moisture. Advanced drying systems, like vacuum drying or air blowers, ensure that parts are completely dry and ready for use or further processing.

4. How often should I maintain my industrial parts washing system?

Regular maintenance is key to ensuring the longevity and efficiency of your washing system. Depending on usage, maintenance tasks such as filter cleaning and equipment inspection should be performed weekly or monthly.

5. How can I ensure that my parts are cleaned to the desired level of precision?

You can ensure precision by using proper settings in the washing system, regularly testing cleanliness through visual inspections, particle counts, and surface analysis, and maintaining the system to operate at its full capacity.