When it comes to drilling holes in metal, a step drill bit is one of the most efficient tools to use. This specialized bit is designed for clean and accurate holes of various sizes without the need for changing bits. Whether you’re a DIY enthusiast or a professional, learning how to use a step metal drill bit properly will make your projects smoother and more efficient. In this guide, we’ll walk you through everything you need to know about using a step drill bit on metal, including tips, safety precautions, and FAQs.

What is a Step Drill Bit?

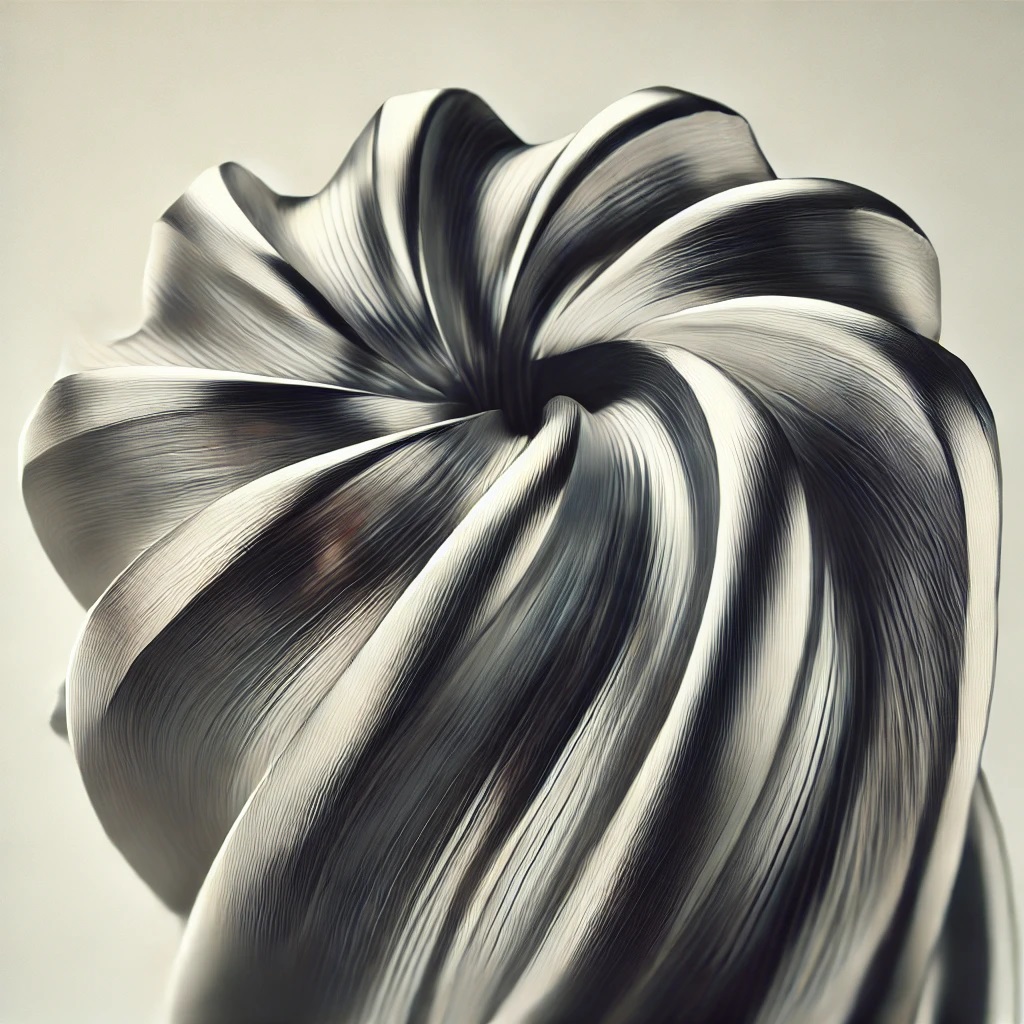

A step drill bit is a conical-shaped tool with multiple steps of different diameters. Each “step” on the bit corresponds to a different size of the hole. This unique design allows the user to create various hole sizes in a single pass, making it incredibly versatile for metalworking. Unlike traditional drill bits, which are cylindrical, step drill bits cut progressively larger holes as they move deeper into the material.

Key Benefits of Using a Step Drill Bit:

- Versatility: One bit for multiple hole sizes.

- Clean, Deburred Holes: Minimal burrs or rough edges.

- Reduced Bit Changes: No need to swap bits for different hole sizes.

- Ideal for Thin Metals: Works perfectly on metal sheets.

Step-by-Step Guide on How to Use a Step Drill Bit on Metal

1. Choose the Right Drill and Bit

Before you begin, ensure you have the appropriate drill and bit for the job. A variable-speed drill or a drill press works best with step bits because you can control the speed more easily. Use a high-quality step drill bit designed for metal to ensure durability.

2. Secure the Metal Sheet

It’s essential to secure the metal sheet before drilling to prevent it from moving or warping. Use clamps or a vice to hold the metal in place. If you’re working with thin metal sheets, consider placing a wooden board underneath to avoid distortion.

3. Mark the Drilling Points

Using a marker or a center punch, mark the exact spot where you want to drill. This will help guide the drill bit and prevent it from slipping during the initial stages of drilling.

4. Set the Drill Speed

Set the drill to a lower speed for drilling metal. Typically, a speed of 500-1000 RPM works well for metal, depending on its thickness. Going too fast can cause overheating and reduce the lifespan of the bit.

5. Lubricate the Drill Bit

To reduce friction and prevent overheating, apply cutting oil or lubricant to the drill bit. This is particularly important when drilling through metal, as it helps prolong the life of the drill bit and ensures smoother cuts.

6. Start Drilling

Place the tip of the step drill bit on the marked point and start drilling at a low speed. Apply firm but controlled pressure, allowing the bit to do the work. As the bit progresses through the metal, it will start cutting larger holes as it moves down the steps.

7. Monitor Progress and Cool the Bit

Check the progress frequently and ensure the drill bit isn’t overheating. If it gets too hot, stop for a moment and let it cool down. You can also add more lubricant to keep the drilling smooth.

8. Complete the Drilling

Once the desired hole size is reached, remove the drill bit. If you need a larger hole, continue drilling until the appropriate step is reached. The step drill bit automatically deburrs the edges as it drills, leaving a clean hole.

9. Inspect the Hole

After drilling, inspect the hole to ensure it’s clean and deburred. If any sharp edges remain, lightly sand or file them down.

Safety Tips When Using a Step Drill Bit

- Wear Safety Gear: Always wear safety goggles, gloves, and ear protection when drilling metal.

- Use Proper Clamps: Ensure the metal is securely clamped to prevent movement.

- Avoid Overheating: Keep the bit cool by using cutting oil and stopping when necessary.

- Maintain Steady Pressure: Avoid pushing too hard on the drill, as this can cause the bit to break or the metal to warp.

Applications of a Step Drill Bit

Step drill bits are versatile and can be used for various tasks, including:

- Electrical Work: Creating holes for conduits or wiring in metal panels.

- Sheet Metal Fabrication: Drilling precise holes in thin metal sheets for industrial and DIY projects.

- HVAC: Drilling holes in ducts and other components.

- Automotive Repairs: Creating or enlarging holes in car body panels and other metal parts.

Frequently Asked Questions (FAQs)

1. Can I use a step drill bit on thick metal?

While step drill bits are excellent for thin metal sheets, they can struggle with thicker metals. For metal thicker than 1/8 inch, consider using a specialized drill bit designed for thicker materials.

2. What type of lubricant should I use when drilling metal?

Cutting oil is the most common lubricant used for drilling metal. It reduces friction and helps prolong the life of the drill bit. Other alternatives include motor oil or WD-40.

3. How do I sharpen a step drill bit?

You can sharpen a step drill bit using a fine grinding wheel. Gently grind the edges of each step, being careful not to remove too much material. However, professional sharpening services can provide more precision.

4. Can I use a step drill bit with a hand drill?

Yes, a step drill bit can be used with a hand drill. Just ensure your drill has variable speed settings, and always drill at lower speeds to avoid overheating.

5. How do I prevent metal from warping when drilling?

To prevent warping, use a backing material like wood underneath the metal sheet. Ensure the metal is properly clamped, and drill at a slow speed with consistent pressure.

Conclusion

A step drill bit is an invaluable tool for metalworking, especially when working with thin metals and needing various hole sizes. By following the steps outlined above, you can achieve clean, accurate holes every time. Remember to take proper safety precautions and maintain your drill bit by using lubricant and monitoring its temperature. With the right technique, your step drill bit will become your go-to tool for all your metal drilling needs.