Introduction

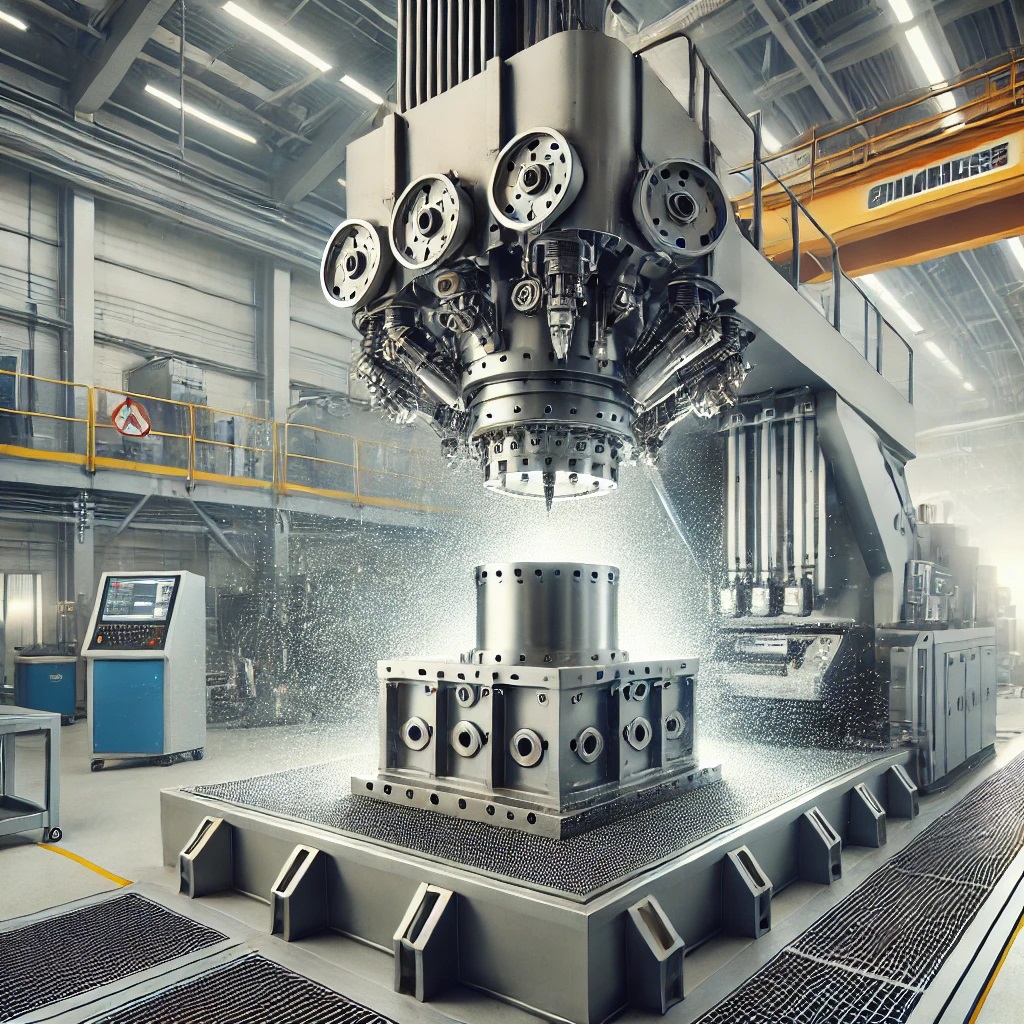

Shot peening has long been a critical process in manufacturing, providing benefits such as increasing fatigue strength and surface durability of metallic components. As industries progress in 2024, new technologies and techniques are revolutionizing this age-old process. With the emergence of automation, digital controls, and improved materials, the shot peening landscape is evolving rapidly.

The Fundamentals of Shot Peening

Shot peening process is a cold working process in which small spherical media, often made of steel, glass, or ceramic, are blasted against the surface of a material. This creates compressive residual stresses on the surface, enhancing fatigue resistance and preventing cracks from forming and propagating.

The key goals of shot peening include:

- Increasing fatigue life

- Enhancing surface strength

- Reducing the risk of stress corrosion cracking

- Improving wear and tear resistance

Technological Advances in Shot Peening in 2024

1. Robotic Automation

One of the most transformative advancements in shot peening is the integration of robotics. Robotic shot peening provides increased precision and consistency, reducing the margin of error associated with manual operations. Robots can perform complex peening tasks with higher repeatability, particularly in industries like aerospace, where precision is paramount.

Key Benefits:

- Enhanced accuracy and consistency

- Ability to handle complex geometries

- Reduced operational costs over time

2. Digital Control Systems

The adoption of digital controls and monitoring systems in shot peening allows real-time tracking and fine-tuning of key parameters such as intensity, coverage, and media size. This ensures more reliable quality control and can improve the longevity of treated parts.

Technological Features:

- Real-time monitoring of peening parameters

- Feedback loops to ensure process consistency

- Data logging for traceability and quality assurance

3. Advanced Materials for Shot Media

In 2024, advancements in shot media materials are pushing the boundaries of what is possible in shot peening. Traditional steel shots are now complemented by advanced ceramic, glass, and even composite media that offer unique advantages such as lower wear, higher impact strength, and tailored particle sizes.

Advantages:

- Reduced media breakdown, leading to longer tool life

- Improved surface finishing with minimal damage

- Customizable media for specialized applications

4. Simulation and Modeling

Simulation technologies now play a crucial role in optimizing shot peening processes. Software tools that model the impacts of different peening parameters allow engineers to predict outcomes and design more efficient peening processes before they are applied in the real world. This reduces trial and error, saving both time and resources.

Key Capabilities:

- Accurate prediction of residual stress distribution

- Optimization of peening coverage and intensity

- Faster design iterations with digital twins

Industries Benefiting from These Advances

Aerospace

Aerospace components such as turbine blades, landing gears, and structural elements demand the highest level of fatigue resistance. The advancements in robotic shot peening and precise digital controls are ensuring that these components can withstand the extreme conditions of flight, while also meeting stringent safety standards.

Automotive

The automotive industry has embraced shot peening for improving the durability of engine components, transmission parts, and suspension systems. With the latest technological advancements, automakers can enhance performance while reducing the weight of components, contributing to better fuel efficiency.

Manufacturing

General manufacturing has also seen significant improvements, especially in tooling and mold production. Shot peening helps extend the life of molds, reducing downtime and the need for frequent replacements.

Emerging Shot Peening Techniques

1. Laser Peening

Laser peening uses high-energy laser pulses to induce compressive stresses without the need for shot media. This technique is highly precise and is used for critical applications where media contamination must be avoided.

Benefits:

- No foreign media contamination

- Extremely high precision

- Suitable for sensitive and high-stress environments

2. Water Jet Peening

Water jet peening uses high-velocity water jets to apply compressive stresses. It is especially useful in industries where surface contamination from shot media is undesirable.

Advantages:

- No surface contamination

- Environmentally friendly

- Ideal for materials sensitive to foreign media

The Future of Shot Peening

As we move further into 2024 and beyond, the shot peening industry is expected to continue evolving with the integration of AI and machine learning. These technologies will further enhance process optimization, allowing for predictive maintenance and real-time adjustments based on the condition of both the equipment and the parts being treated.

Additionally, sustainability is becoming a growing concern. Future shot peening processes are likely to focus on reducing environmental impact by minimizing energy consumption, waste media, and using greener alternatives.

FAQs

1. What is shot peening used for?

Shot peening is primarily used to improve the fatigue resistance of metal components by inducing compressive residual stresses on the surface, preventing crack propagation and enhancing durability.

2. How does robotic shot peening differ from traditional methods?

Robotic shot peening offers higher precision, consistency, and the ability to handle complex geometries, reducing the margin of error compared to manual methods.

3. What are the benefits of digital control systems in shot peening?

Digital control systems allow for real-time monitoring and adjustment of shot peening parameters, ensuring better process consistency and quality control.

4. Are there eco-friendly shot peening techniques available?

Yes, techniques like water jet peening and the use of advanced media reduce environmental impact by eliminating foreign contaminants and lowering energy consumption.

5. What industries benefit the most from shot peening advances?

Industries like aerospace, automotive, and manufacturing benefit the most due to the high demands for fatigue resistance, precision, and durability in their components.

Conclusion

Shot peening in 2024 is experiencing a transformation driven by technological advancements like robotics, digital controls, and innovative materials. These innovations are pushing the boundaries of what can be achieved in terms of precision, efficiency, and sustainability. As industries such as aerospace, automotive, and manufacturing continue to demand high-performance components, the adoption of these cutting-edge techniques will play a crucial role in improving product durability, reducing costs, and ensuring better environmental practices. Looking ahead, technologies like AI and machine learning promise to further refine and optimize shot peening, making it an indispensable tool for modern engineering solutions.